Which Powder Filling Machine Is Best for Small Businesses in 2025

Key Takeaways

Choose a powder filling machine that fits your budget, space, and production needs to save money and improve efficiency.

Semi-automatic fillers like auger model offer a great balance of accuracy, speed, and cost for small businesses.

Consider machine features such as ease of use, maintenance, and scalability to support your business growth.

Match your powder type and daily output to the right machine type, from manual to fully automatic, for best results.

Test machines with your own powder and seek expert advice to ensure the machine meets your current and future needs.

Choosing Criteria

Cost and Budget

You need to balance the initial price with long-term savings.

Look at both the upfront investment and ongoing costs like labor, energy, and material waste.

Machines with higher accuracy can save you money by reducing waste.

Consider financing options and available support.

Cost Factor | Starter Model | Mid-Range Model | Hybrid Pro Model |

|---|---|---|---|

Annual Labor Cost | $31,200 | $18,720 | $9,360 |

Energy Costs | $1,440 | $1,008 | $864 |

Material Waste | 12% | 6% | 3.5% |

5-Year Total Cost | $176,400 | $109,760 | $85,680 |

Tip: A powder filling machine with better accuracy and automation can lower your total costs over time.

Size and Space

Measure your workspace before choosing a machine.

Smaller machines fit better in tight spaces and are easier to move.

Vertical and desktop models work well for small shops.

Note: Compact machines help you use your space more efficiently.

Speed and Accuracy

Match the machine’s speed to your daily production needs.

Higher speed means more units packed per day, but you must also check accuracy.

Accurate machines reduce waste and keep your product quality high.

Production Line Size | Daily Capacity (units) | Recommended Speed (Packs/Min) |

|---|---|---|

Small | 1,000 – 5,000 | 50 – 100 |

Medium | 5,000 – 20,000 | 100 – 200 |

Large | Over 20,000 | 200+ |

Ease of Use

Choose a machine with simple controls and clear instructions.

User-friendly designs help your team learn quickly and avoid mistakes.

Training and support from the supplier make setup easier.

Many small business owners report high satisfaction with machines that have intuitive interfaces and hands-on training.

Maintenance and Support

Regular cleaning and calibration keep your machine running smoothly.

Good after-sales support includes warranty, spare parts, and technical help.

Reliable support reduces downtime and protects your investment.

Many suppliers offer video assistance, online troubleshooting, and on-site repair services.

Scalability

Think about your future growth.

Pick a machine that can handle more volume as your business expands.

Some machines allow you to add more heads or upgrade features.

Tip: Planning for scalability helps you avoid buying a new machine too soon.

Powder Filling Machine Types

Manual Fillers

Manual fillers give you full control over the filling process. You operate these machines by hand, usually with a single nozzle. They work best for very low production volumes or when you need to fill thick or sticky powders. Manual fillers cost less than other types and are easy to maintain. You can use them in small workshops or when starting your business.

Simple design and low cost

Best for startups or small batches

Require full human operation and have lower output

Note: Manual fillers suit you if you want to keep costs down and do not need high speed.

Semi-Automatic Fillers

Semi-automatic fillers, such as HONGDI’s auger powder filling machine, combine automation with manual handling. You place the container, and the machine fills it with precise amounts. This type increases your speed and accuracy compared to manual fillers. You can use them for low to medium production volumes. They fit many packaging formats and reduce downtime because they need less maintenance.

Lower maintenance and cost-effective

Fast and efficient for small-scale production

Flexible for different container types

Semi-automatic fillers help you meet production demands without losing quality. You get a good balance between investment and output.

Automatic Fillers

Automatic fillers handle the entire filling process with little human help. You can use them for medium to large production runs. These machines, including HONGDI’s fully automatic auger and cup fillers, deliver high speed and accuracy. They reduce labor costs and improve safety. You can expect consistent results and less waste.

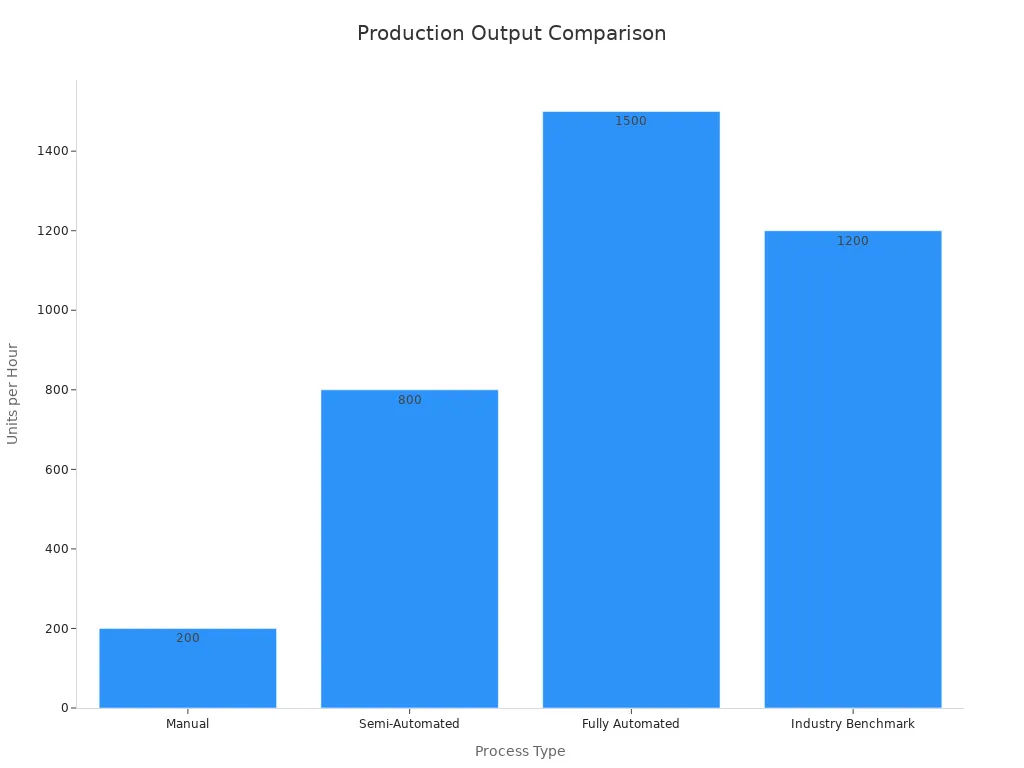

Metric | Manual Process | Semi-Automated | Fully Automated |

|---|---|---|---|

Output (units/hr) | 200 | 800 | 1,500 |

Error Rate (%) | 10% | 4% | 1% |

Labor Hours/Shift | 24 | 12 | 6 |

Downtime (min/day) | 60 | 20 | 5 |

Automatic fillers work best if you want to scale up and need high efficiency.

Sachet and Stick Pack Machines

Sachet and stick pack machines fill powders into small, single-use packets. You can use these for products like instant coffee, spices, or supplements. These machines save space and materials by using flexible packaging. They work well for businesses that want to offer sample sizes or portion-controlled products.

Great for small packets and flexible packaging

High output in a compact design

Ideal for food, beverage, and nutraceutical industries

Vertical Fillers

Vertical form-fill-seal (VFFS) machines fill and seal powders in a vertical orientation. You can fit these machines into tight spaces. They produce bags or pouches quickly and efficiently. HONGDI’s vertical fillers support flexible packaging and use less floor space.

High-speed operation for bags and pouches

Real-time monitoring and easy maintenance

Tip: Choose vertical fillers if you need to maximize output in a limited space.

Intelligent Weighing Fillers

Intelligent weighing fillers use advanced sensors and controls to measure powders with high accuracy. HONGDI’s vacuum fillers use vacuum-pressure dosing to handle fine or fluffy powders. You get consistent dosing and minimal waste. These machines clean themselves between fills, keeping your product pure.

High precision for fine powders

Adjustable dosing for different products

Reliable and easy to calibrate

You can trust intelligent weighing fillers for products that need exact amounts, such as pharmaceuticals or specialty foods.

Best Powder Filling Machine Models

Semi-Automatic Auger Filler

You want a machine that gives you both accuracy and flexibility. The Semi-Automatic Auger Filler stands out for small businesses. You can use it for many types of powders, from spices to milk powder. This model fits well in small spaces and does not need much training to operate. You can adjust the auger size and speed for different products and containers. Digital controls help you get consistent fills every time.

Lower upfront cost than fully automatic machines

Simple design for easy setup and quick training

Handles a wide range of powders and container sizes

Digital controls reduce waste and errors

Small footprint fits tight workspaces

Supports small batch and specialty runs

You can boost your production speed compared to manual filling. Many companies report better packaging consistency and lower labor costs with this model. If you want a balance of quality, efficiency, and cost, this is a top choice.

Manual Powder Filler

If you run a startup or need to fill small batches, the Manual Powder Filler gives you control and simplicity. You operate this machine by hand, so you can adjust the fill amount as needed. This model works well for thick or sticky powders and does not require electricity. You can clean and maintain it easily, which helps you keep costs low.

Best for very small production runs or specialty products

No need for complex setup or power supply

Easy to clean and maintain

Low initial investment

You can use this powder filling machine in small workshops or when you want to test new products. It helps you keep your business flexible and your costs under control.

Desktop Automatic Filler

You may want more speed without losing accuracy. The HONGDI Desktop Automatic Filler fits on a table and automates the filling process. You can use it for medium-sized batches and get consistent results. The compact design saves space, and the user-friendly interface makes operation simple.

Feature | Benefit for Small Business |

|---|---|

Compact size | Fits on standard workbenches |

Automated filling | Increases speed and accuracy |

Easy controls | Reduces training time |

Quick changeover | Supports multiple powder types |

You can rely on this model for daily production needs. It helps you grow your business without needing a large factory floor.

Sachet Packing Machine

If you want to offer single-serve or sample packs, the Sachet Packing Machine is a smart pick. You can fill powders into small sachets or stick packs quickly. This machine uses flexible packaging, which saves material and storage space. You can use it for products like instant coffee, spices, or supplements.

High output for small packets

Flexible packaging options

Ideal for food, beverage, and health products

Saves space and materials

You can attract new customers with sample sizes or portion-controlled products. This model helps you expand your product line and reach new markets.

Intelligent Weighing Filler

You need high precision for some powders, such as pharmaceuticals or specialty foods. The Intelligent Weighing Filler uses advanced sensors to measure each dose. You can adjust the settings for different products and get reliable results every time. The machine cleans itself between fills, which keeps your product pure.

High accuracy for fine or fluffy powders

Adjustable dosing for various products

Self-cleaning for product safety

Easy calibration and setup

You can trust this model when you need exact amounts and top product quality. It supports your business as you move into more demanding markets.

Tip: Choose the model that matches your current needs and future growth plans. HONGDI offers expert support to help you select and set up the right machine.

Decision Guide

Assessing Needs

Start by looking at your business goals. Think about how many units you want to fill each day. Check the type of powder you use. Some powders are fine and light, while others are heavy or sticky. Measure your workspace. Write down your budget. These steps help you understand what you need from a powder filling machine.

Tip: Make a checklist with your daily output, powder type, available space, and budget. This will help you stay focused.

Matching to Machine Type

Now match your needs to the right machine. If you fill only a few containers each day, a manual filler works well. For medium batches, choose a semi-automatic model. If you want to fill many units quickly, look at automatic or intelligent weighing fillers. Use a simple flowchart to guide your choice. Start with your production volume, then check powder type and space. This method is similar to how experts use algorithms and flowcharts to pick the best machines for complex tasks.

Need | Best Machine Type |

|---|---|

Small batches | Manual Filler |

Medium batches | Semi-Automatic Filler |

High speed & volume | Automatic/Weighing Filler |

Small packets | Sachet Packing Machine |

Evaluating Features

Look at the features of each machine. Check if the controls are easy to use. See if the machine can handle your powder type. Make sure it fits your workspace. Ask about cleaning and maintenance. Look for machines that let you upgrade or add new features as your business grows.

Note: User-friendly controls and easy cleaning save you time and money.

Making the Choice

After you compare your needs and the machine features, make your choice. Pick the powder filling machine that matches your goals and space. If you feel unsure, talk to experts. They can help you test products and answer your questions. You get support before and after your purchase.

Tip: Testing a machine with your own powder helps you see real results before you buy.

You want a solution that grows with your business and keeps quality high. HONGDI’s semi-automatic auger model stands out because it offers:

Fast, accurate filling for many powder types and container sizes

Easy adjustments and quick changeovers for small batch runs

Lower costs and simple training for your team

Reliable support and easy maintenance

Experts say these machines help you save money, boost productivity, and meet industry standards. Before you buy, review your production needs and growth plans. Reach out to trusted suppliers like HONGDI for expert advice and product demos.

FAQ

What types of powders can powder filling machines handle?

You can fill a wide range of powders, including milk powder, spices, protein supplements, and fine pharmaceutical powders. HONGDI machines work well with both free-flowing and non-free-flowing powders.

How do you choose the right powder filling machine for your business?

Start by listing your daily output, powder type, available space, and budget. Use this checklist to compare machine features. You can also ask HONGDI for expert advice and product testing.

Tip: Testing your own powder on the machine helps you make the best choice.

How often should you clean and maintain your powder filling machine?

You should clean your machine after each production run. Regular maintenance, such as calibration and dust removal, keeps your machine accurate and reliable.

Task | Frequency |

|---|---|

Cleaning | After each run |

Calibration | Weekly |

Inspection | Monthly |

Can you upgrade your powder filling machine as your business grows?

Yes, you may add new features, increase filling heads, or improve automation. This helps your machine keep up with your growing production needs.

Add more filling heads

Upgrade software

Increase automation