Snack Packaging Machine Comparison Find the Right Fit for 2025

For 2025, the best snack packaging machine is different for each business. Each company has its own products and goals. Companies work better when they pick machines that fit their needs. New technology like automation, AI, and eco-friendly designs are changing the market. These new ideas help businesses keep up and meet what customers want.

Key Takeaways

Picking the right snack packaging machine helps you work faster. It makes your snacks better and saves money by cutting waste and stopping delays.

Some machines work best for certain snacks. VFFS is good for chips and granola. Flow wrappers are best for bars and cookies. Multihead weighers are used for nuts and mixes. Thermoforming is for snacks that break easily.

New tech like automation and AI makes packing faster. It helps stop mistakes and lets you switch snacks quickly to match what people want.

Caring for the planet is important. Many machines now use green materials and smart designs. This helps companies make less harm to the earth.

Companies should choose machines that fit their size, money, and snack types. They should also pick suppliers who give good help and quick service.

Why Machine Choice Matters

Efficiency

Picking the right snack packaging machine can change how a factory works. Machines with automation and AI can make things faster and more accurate. These tools help workers make fewer mistakes. They also help keep the machines running well. AI can change settings quickly and tell when repairs are needed. This means less time when machines stop and more snacks get packed.

Machine Type | Speed Improvement (%) | Cost Savings (%) | Waste Reduction (%) | Output (pouches/hr) | Downtime (hrs/yr) |

|---|---|---|---|---|---|

VFFS | Up to 70 | Up to 50 | 4-5 | 4,800 | 24 |

Premade Pouch | - | Up to 50 | - | - | 36 |

Manual (baseline) | - | 0 | - | - | 120 |

Modern factories watch numbers like OEE, scrap rates, and cycle times. These numbers show how well machines work. Managers use them to find ways to do better.

Product Quality

The machine you pick changes how good your snacks look and taste. Good machines make every package the same. They keep snacks fresh and safe by sealing bags tight and filling them right. For example, VFFS machines can fill bags almost perfectly. Manual packing can be off by a lot more. This means less waste and better snacks in stores.

Note: When packages always look good, customers trust the brand more. This helps the brand get noticed in busy stores.

Cost Impact

The best machine can help save money in many ways. Fast machines use less stuff and less power. They also need fewer people because they do more jobs by themselves. Companies that buy new machines often get their money back fast. For example, using a VFFS machine can cut costs by half compared to packing by hand. Less waste and fewer stops also help save money.

Picking the right snack packaging machine is not just about speed. It helps make work better, snacks better, and helps the business earn more money.

Snack Packaging Machine Types

Snack companies use different packaging machines for their products. Each machine has special features and helps in its own way. Companies like HONGDI sell many types of these machines. Some are ready to ship fast.

The food packaging market is getting bigger every year. People want many kinds of packaging.

There are different packaging types like pouches, trays, and bottles. These match the main kinds of packaging machines.

New machines use eco-friendly materials and smart technology. This helps the planet and makes work easier.

More people want snacks that are ready to eat or come in small packs. This means companies need special snack packaging machines.

Vertical Form Fill Seal (VFFS)

VFFS machines make, fill, and seal bags from the top down. They are good for powders, small snacks, and granules. Their small size fits in tight spaces and helps make snacks fast.

Specification Aspect | Details |

|---|---|

Packing Range | 1-15 kg |

Maximum Film Width | 800 mm |

Packing Speed | 25–45 bags per minute |

Maximum Bag Size (L × W) | 80–500 mm × 100–370 mm |

Bag Type | Pillow bag |

Packaging Material | Thermoplastic laminated film |

Automation Level | Automatic |

VFFS machines use smart controls to pack snacks quickly and the same way each time.

Flow Wrapper

Flow wrappers are also called horizontal form fill seal machines. They wrap snacks in a long sheet of film. These machines are good for snacks that are solid, break easily, or have odd shapes. They can make pillow packs and bags with folds. This lets companies pack many snack types.

Multihead Weigher

Multihead weighers have many heads to weigh snacks. They give the right amount every time. These machines are best for snacks like chips or nuts that need exact portions. They work fast and help save snacks from being wasted.

Premade Pouch

Premade pouch machines fill and close pouches that are already made. They can pack liquids, powders, and solids very carefully. They fill pouches almost perfectly, up to ±0.1%. Features like dust control keep snacks clean and safe. These machines can seal, label, and check pouches by themselves.

Thermoforming

Thermoforming machines heat and shape plastic sheets into trays and containers. They make packages that are always the same size and thickness. These machines use less material and can use recycled plastic. The packages are light, so shipping costs less.

Custom shapes help snacks fit well and stay safe when moving.

These machines work fast and let companies make many designs. That is why they are popular for snacks.

Stick Packaging

Stick packaging machines make thin, single-serve packets. They are good for powders, coffee, and liquids. These packets are easy to carry and help people eat snacks on the go.

HONGDI is a top supplier with many snack packaging machines. They have machines in stock for fast shipping. Their machines help companies keep up with new trends and what customers want.

How They Work

Snack packaging machines use steps to keep snacks fresh and safe. Each machine has its own way to handle snacks and packaging. The table below shows the main steps and how well modern machines work:

Process Step | Description / Operational Detail |

|---|---|

Mixing | First, ingredients are blended to make them the same |

Conveying | Materials move from one step to the next |

Extrusion | Snacks are shaped or formed here |

Drying | Moisture is taken out for texture and longer shelf life |

Crushing | Snacks are broken down to the right size |

Mixing (again) | Ingredients are blended again for evenness |

Packaging | Snacks are sealed to keep them fresh and clean |

Performance Benchmark | Description / Operational Standard |

|---|---|

Precision Dosing | Snacks are measured within ±1% for quality |

Hygienic Design | Machines use stainless steel to stay clean and safe |

Modular Design | Machines can be changed or added to easily |

Packaging Integrity | Packages stay fresh and keep out germs |

VFFS Process

A VFFS machine makes a bag from flat film. It fills the bag with snacks and seals it shut. Workers put film rolls in and set up the machine. The machine cuts, fills, and seals bags all at once. Sensors check if bags are filled and sealed right.

Flow Wrapper Process

A flow wrapper covers snacks with a long sheet of film. The machine folds the film and seals the sides. A cutter splits each snack into its own pack. This works well for bars, cookies, and solid snacks.

Multihead Weigher Process

A multihead weigher uses many heads to weigh snacks. The machine puts the right amount in each pack. It checks the weight and fixes it if needed. This helps give the same amount every time and saves snacks.

Premade Pouch Process

A premade pouch machine grabs empty pouches. It opens, fills, and seals each pouch. Dust control and checks keep things clean and safe. Workers can change pouch sizes fast.

Thermoforming Process

A thermoforming machine heats plastic sheets to make trays. It fills each tray with snacks and seals them with film. This makes strong, even packages that protect snacks when shipped.

Stick Packaging Process

A stick packaging machine makes thin tubes from film. It fills each tube with powder or liquid and seals both ends. This makes small packets that are easy to carry and use.

Note: Every machine type follows strict rules for cleanliness and quality. These rules help companies give customers safe and fresh snacks every time.

Best-Fit Products

Snacks for VFFS

Vertical Form Fill Seal (VFFS) machines can pack many snack types. They work best with snacks that move easily and need quick packing. Companies use VFFS machines for snacks like:

Potato chips

Pretzels

Popcorn

Granola

Trail mix

VFFS machines help snacks stay fresh and get packed fast. They are good for both big and small snack companies.

Snacks for Flow Wrapper

Flow wrappers are great for solid snacks that need gentle care. These machines wrap each snack in film to keep it safe. Snacks often packed with flow wrappers are:

Candy bars

Cookies

Crackers

Rice cakes

Energy bars

Flow wrappers help snacks look nice and stay safe while shipping.

Snacks for Multihead Weigher

Multihead weighers make sure each bag has the right amount. They are best for snacks that need exact weights. Some snacks packed this way are:

Mixed nuts

Dried fruit

Gummy candies

Cheese balls

Snack mixes

Snack Type | Portion Accuracy | Speed |

|---|---|---|

Mixed nuts | High | Fast |

Gummy candy | High | Fast |

Snacks for Premade Pouch

Premade pouch machines can pack many snack kinds. They work with both dry and wet snacks. Snacks often packed with these machines include:

Jerky

Dried seaweed

Yogurt-covered snacks

Chocolate-covered fruits

Snack powders

Tip: Premade pouch machines let brands use cool pouch shapes and resealable pouches.

Snacks for Thermoforming

Thermoforming machines make strong trays and boxes for snacks. They are best for snacks that need extra care or special shapes. Good snacks for these machines are:

Sliced cheese

Meat snacks

Fresh-cut fruit

Mini cakes

Delicate pastries

Thermoformed packs keep snacks safe and help them last longer.

Snacks for Stick Packaging

Stick packaging machines make thin, single-serve packets. These are good for snacks people eat on the go. Snacks packed this way are:

Instant coffee

Drink mixes

Protein powders

Sugar sticks

Flavored salts

Stick packs are easy to carry and help with portion control.

2025 Features & Trends

Automation & AI

Automation and AI are changing snack packaging machines. Companies use AI to do boring jobs like peeling and packing. AI vision systems look for problems and keep snacks safe. These systems also help with safety checks and make fewer mistakes. Many factories use servo-driven filler-capper monoblocks for better speed and accuracy. Cobot palletizers help make changeovers faster and stack products quickly. AI also checks packaging designs, so brands can sell new products sooner.

Market research says AI helps companies work better by making production faster and checking quality. These new tools help companies keep up with orders and waste less.

Speed & Flexibility

Snack packaging machines in 2025 need to be fast and flexible. Automation helps companies switch snacks quickly. Servo-driven systems and dosing make machines work faster. Flexible machines can pack different bag sizes and styles without long stops. This helps brands follow new trends and pack seasonal snacks.

Automation means fewer jobs done by hand.

Machines can change snacks with little waiting.

Companies can fill orders faster.

Sustainability

Sustainability is making snack packaging change a lot. Companies use lighter and recycled materials to help the planet. For example, Johnnie Walker made a much lighter bottle. Dole used less plastic wrap by using recycled wrap. Real-time data helps companies watch how much they use and waste.

Big events like Pack Expo Southeast and Sweets & Snacks Expo show that more people want green packaging.

Material Options

New materials help companies do better for the earth and their products. Sustainable materials like cross-laminated timber and low-carbon concrete use less energy. Factories get cleaner air and better soil by using these materials and dust control. PM10 and PM2.5 levels drop a lot, and soil gets healthier. These changes make work and the planet safer.

Snack packaging machine suppliers now have machines for many eco-friendly films and recyclable materials. This helps brands stay ahead in a world that cares about the earth.

Snack Packaging Machine Comparison

Speed & Capacity

Speed and capacity are very important when picking a snack packaging machine. Companies want machines that pack snacks fast and meet demand. New machines use smart controls to go faster and stop less. Workers watch numbers to see how well machines work. They look at things like Overall Equipment Effectiveness (OEE), capacity use, and throughput.

Metric | Description | Formula |

|---|---|---|

Overall Equipment Effectiveness (OEE) | Combines availability, performance (speed), and quality | OEE = Availability × Performance × Quality |

Availability | Percentage of time equipment is available for production | - |

Performance | Percentage of maximum speed at which equipment operates | - |

Quality | Percentage of good products produced | - |

Capacity Utilization Rate | Percentage of actual output over maximum potential output | Capacity Utilization Rate = (Actual Output / Maximum Potential Output) × 100% |

Production Rate | Quantity of products produced per unit time | Production Rate = Number of Units Produced / Time Taken |

Throughput | Quantity of products passing through a production stage per unit time | Throughput = Number of Units Processed / Time Taken |

Engine Load Factor tells how hard a machine works. For example:

A tractor’s Engine Load Factor was 60% for 30 days.

Higher numbers mean the machine works more during busy times.

Lower numbers mean the machine is not working much.

These numbers help managers plan when to use or fix machines.

Snack companies use these numbers to choose the right machines. Machines with high OEE and capacity use help pack more snacks and waste less.

Product Compatibility

Product compatibility means how well a machine packs different snacks. Some machines are best for powders or granules. Others work better with solid snacks or liquids. Companies want machines that can switch snacks quickly.

Innovation / Case Study Aspect | Description | Impact on Product Compatibility and Operations |

|---|---|---|

Real-time Inventory Tracking | Advanced software provides live snack inventory data | Keeps machines stocked with fresh snacks, improves efficiency |

AI-powered Personalized Recommendations | AI suggests snacks based on user preferences and purchase history | Matches snack options to individual tastes and dietary needs |

Cashless Payment Integration | Supports NFC, mobile payments, QR codes, and cryptocurrency | Speeds up transactions, improves user experience |

Centralized Control Across Locations | Operators manage multiple machines remotely | Makes it easy to scale and keep products consistent |

Sustainability Initiatives | Uses eco-friendly practices and healthier snack options | Expands product range and meets health and environmental trends |

Case Studies of Small Operators | Customizable interfaces and healthier options improve business growth | Shows real-world gains from smart machine features |

Future-ready Features | Personalization, interactivity, maintenance automation, custom branding | Supports diverse snacks and builds customer loyalty |

Note: Machines with smart software and AI can pack many snack types. They help companies give more choices and follow new trends.

Unique Innovations

Snack packaging machines in 2025 have cool new features. Real-time inventory tracking lets workers see snack levels and avoid running out. AI systems suggest snacks based on what people like. Cashless payment makes buying snacks quick and easy.

Now, operators can control many machines from one place. This helps them check inventory, fix problems, and keep things safe at different sites. Machines also use green materials and offer healthier snacks. These changes help companies meet what customers want and stay ahead.

Future-ready machines have:

Snack personalization

Interactive screens

Automatic maintenance alerts

Custom branding

These new features help companies grow, reach more people, and make customers loyal.

Choosing the Right Snack Packaging Machine

Business Size

How big a business is changes what machine it needs. Small and medium businesses want machines that are not too expensive. They also want machines that are fast and can do different jobs. Big companies need machines that pack snacks very fast. They need machines that can handle lots of snacks at once. The table below shows which machines work best for each business size and snack type:

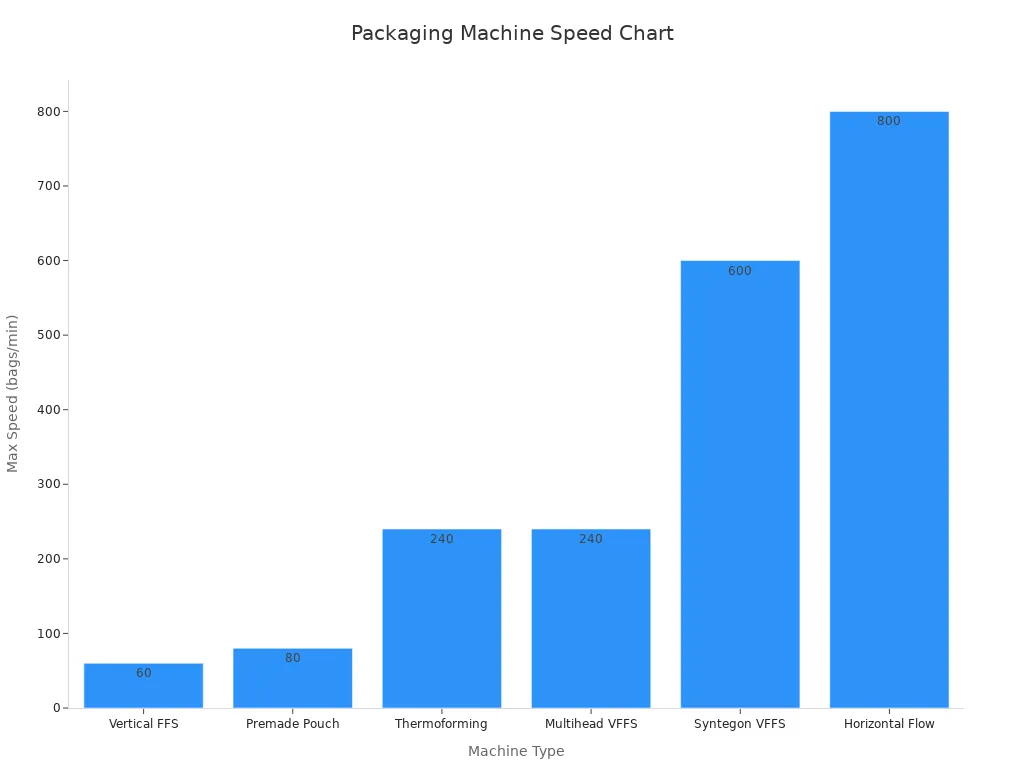

Machine Type | Max Speed (bags/min) | Key Innovations | Suitable Business Size & Applications |

|---|---|---|---|

Premade Pouch | 80 | AI-driven vision, nitrogen flushing | SMEs, regional snacks like chips, nuts, trail mixes |

VFFS (Lintyco) | 60 | Servo-driven feeders | SMEs, granules, powders |

Flow Wrapper (Bosch) | 800 | High-speed automation | Large-scale, biscuits, chocolate, frozen snacks |

Thermoforming | 240 | Vacuum/MAP, energy efficient | SMEs scaling up, protein-based snacks |

Multihead Weigher+VFFS | 240 weighments/min | Anti-static, waterproof | Large operations, crisps, jerky, mixed nuts |

VFFS (Syntegon) | 600 | Mono-material films, recyclable | Large-scale, sustainable packaging |

Product Type

The kind of snack decides which machine is best. Powders and granules go with VFFS machines. Solid snacks like bars or cookies use flow wrappers. Snacks that break easily or spoil fast need thermoforming. Multihead weighers are good for snacks that are mixed or need exact amounts. Companies should pick machines that match what their snacks need.

Budget

How much money a business has changes what machine they buy. Small and medium businesses pick machines that cost less and can do many things. Big companies spend more on machines that work very fast and by themselves. Now, there are machines for every budget. New machines use automation, AI, and green features to help all businesses save money.

Tip: Buying a machine that can grow with your business helps save money later.

Support & Service

Good support helps machines work well every day. Companies should pick suppliers who teach workers and fix machines fast. They should also send parts quickly when needed. HONGDI has many snack packaging machines and helps after you buy. Talking to expert suppliers helps companies find the best machine for their needs.

Picking the best packaging in 2025 means looking at speed and how easy it is to change. New technology is important too. Companies notice that people want healthier snacks and care about the environment. Digital tools are also changing how snacks are packed.

Shoppers like packaging that looks cool and is easy to use. They want it to show health facts.

Brands pick recyclable materials and smart labels. They use seals that show if a package was opened to help people trust them.

Small, easy-to-carry, and resealable packs are good for busy people.

Companies need to choose machines that fit their snacks and what they want to do. Talking to experts helps them pick the right machine. Learning about new trends helps companies stay ahead.

FAQ

What is the most popular snack packaging machine for 2025?

VFFS machines are still the favorite for snack makers. They work fast and seal bags well. These machines are used for chips, popcorn, and granola. Companies like them because they pack snacks quickly and the same way every time.

How does automation improve snack packaging?

Automation makes packing snacks faster and easier. Machines do the same jobs over and over without getting tired. They check if snacks are packed right and tell workers if something is wrong. This means more snacks get packed with fewer mistakes and less waiting.

Can one machine handle different snack types?

Many new machines can pack lots of snack kinds. Multihead weighers and premade pouch machines are good examples. Workers can change the settings for each snack. This lets companies switch snacks fast and not waste time.

What packaging materials work with these machines?

Most snack packaging machines use many kinds of packaging. They work with recyclable films, laminates, and compostable wraps. Companies pick what works best for their snacks and to help the planet.

How fast can snack packaging machines operate?

How fast a machine works depends on its type. Flow wrappers can pack up to 800 snacks each minute. VFFS machines usually pack 25 to 60 bags every minute. Companies choose machines based on how many snacks they need to pack and what kind of snack it is.

See Also

Top Powder Filling Machines Ideal For Small Businesses In 2025